产品概述

Product description

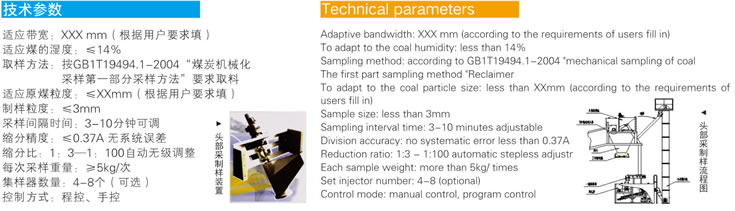

自动皮带采制样装置是在吸收国外先进技术经验基础上,根据国内工业现状而设计开发的系列产品。它实现了对被采集物料进行全断面取样,与皮带输送机实现连锁,能够从采样、破碎、缩分、集样、余料返回整个过程全部自动化,使取样具有代表性。广泛应用于冶金、化工、煤炭、港口等行业。

自动皮带采制样装黄可分为BLCYZ皮带中部采样装置和BLCYT皮带头部采样装置。

采样工艺符合GB/T19494-2004国家标准要求

Belt automatic sampling device is In the absorption of foreign advanced technology and experience. according to the present situation of domestic industry and the design and development of series products It achieves the collected materials full section sampling.and the belt conveyer to achieve linkage from sampling. crushing. reduction, set. morethan expected to return the whole process is automatic, make sampling representative

Widely used in metallurgy, chemical industry, coal. port and other industries

Automatic belt sampling devlce can be divided into BLCY-Z belt middle sampling device and BLCYT belt head sampling device

Sampling process n line with GB/T19494-2004 national standards

设备组成/Equipment components

BLCY-Z皮带中部采样装置主要由以下部件组成璇转采样头、初级皮带给料机、破碎机、二级皮带给料机、缩分器、样品收集器、斗式提升机、余料返回系统以及电气控制系统组成。

BLCY-Z belt ln the central sampling device mainly by the following components:rotary sampling head. the primary belt feeder. crusher. two belt feeder. shrinkagedivider. sample collector. bucket holist. excess stock return system and electric control system composed of.

工作流程/Work process

初级采样头与主皮带连锁,按照设定的时间间隔,采样头旋转周,从运动的带式输送机上取得一个完整的横截面的子样,子样通过溜槽落人初级皮带给料机,由初级皮带给科机将物料均匀地送八破碎机。破碎机将物料破碎到所要求的粒度,由二级皮带给料机经缩分器缩分出样品,最后样品被收集到防水、防尘的容器中。采样系统中的余料通过斗式提升机返回到输煤系统带式输送机上。

BLCY-Z belt in the central sampling device maInly by the following components:rotary sampling head. the primary belt feerjer. crusher. two belt feeder. shrinkagedivider. sample collector. bucket hoist. excess stock return system and electriccontrol system composed of Pnmarysampnng head and main belt chain. according to the set time intarval.sampling head rotation of one week. from movement together with the conveyor has a complete crosssection sample. sample through a chute fall into primary belt feeder, feeder by the pnmary belt material evenly send into the crusher Crusher material is crushed to the required size, by the secondary belt feeder through the shrinkage divider shrinkage separation of samples. the sample were collected to waterproof and dustproof container. Over sampling in feeding system by the bucket elevator to return to the coal handling system of belt conveyor.