当前位置:首页 > 产品中心 > 失重秤、实物标定装置、链码、缓冲秤

当前位置:首页 > 产品中心 > 失重秤、实物标定装置、链码、缓冲秤

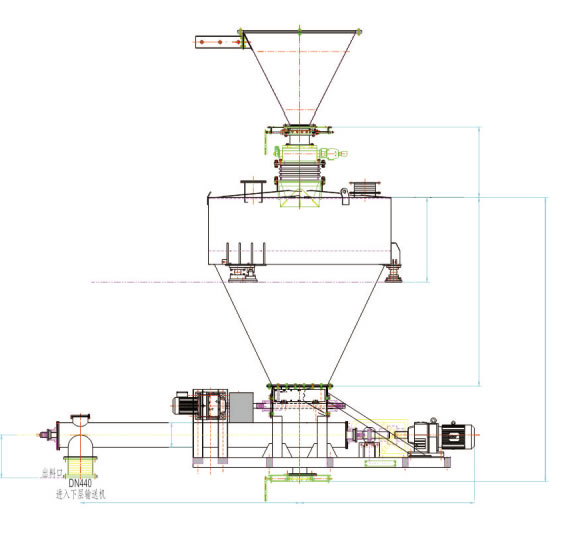

百灵DCS系列减量秤,又称为失重秤,是一种间断给料连续出料的称重设备,由于失量控制是在料斗中进行,可达到较高的控制精度,全密封结构,无环境污染,故在粉料控制时与用螺旋秤来相比是一大提高。适用于水泥、石灰粉、煤粉等微细物料的控制配料。

根据称重斗中物料重量的减少速率来控制出料螺旋机或给科机,以达到定量给料的目的,即减量秤,当称重斗的物料达到称重下限位置时,出料螺旋机则按照当时的转速固定出料晕,同时控制料仓里的物料快速下到称重斗内,当装料到称重上限时停止装料,快速装料可以缩短给料时间,提高称重的准确度和控制精度。

According to the weighing bucket in material weight reduction rate to control discharge screw conveyor or feeder. to achieve the quantitative data, ie. reduction scale. when the weighing bucket material to weighing the lower limit position. spiral machine according to the speed at the time of the fixed quantW of the discharging and controlling the material warehouse material rapidly down to the weighing hopper. when charging to the weighing limit stop charging, fast charging can relationship to feeding time and improve the accuracy of weighing and control precision

适用范围连续式稳定土、混凝土搅拌站水泥配料煌结定量控制给料,煤粉定量控制给料及各种浓浆料的配料等。